Check Valve Symbol Variations and Their Uses in Different Industries

Check valves are essential components in various industries, used to ensure the flow of liquids or gases in one direction only, preventing reverse flow that could cause damage to equipment or systems. These valves come in different types and symbols, each tailored for specific applications. Understanding the symbol variations and their uses is critical in selecting the appropriate check valve for a particular system. The most common symbol for a check valve is a simple representation of a valve with a spring-loaded disk or ball. In engineering schematics, the check valve symbol typically appears as a circle or square with a line representing the flow path. The symbol may also feature a directional arrow, indicating the allowed flow direction. The variations in the symbols often correspond to the valve type, which determines how the valve operates. One of the primary variations in check valve symbols is the spring check valve, which features a spring that helps close the valve when the flow direction reverses.

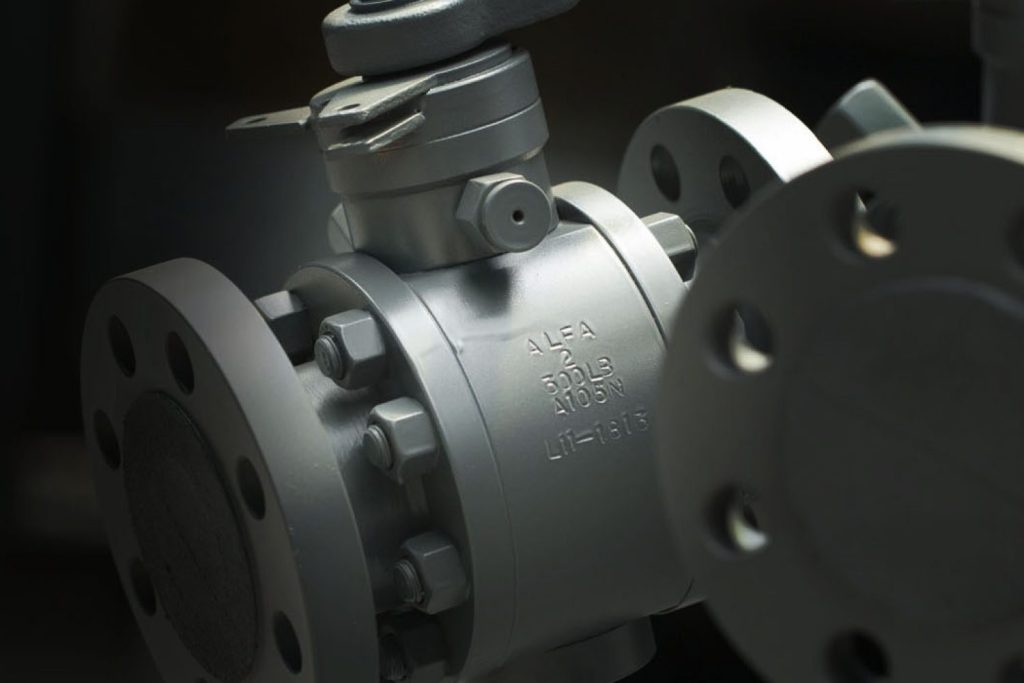

This spring-loaded mechanism provides a more reliable seal, preventing backflow even under fluctuating pressures. In schematics, this is often represented by a symbol with a spring or coil next to the valve body. These valves are widely used in applications where the flow is intermittent or where the system pressure can fluctuate, such as in water treatment plants or hydraulic systems. Another variation is the ball check valve, where a ball is used to block reverse flow. In the symbol, a circle may represent the ball, with an arrow indicating the direction of flow. This type of check valve is commonly used in smaller systems or where space is constrained, as the ball mechanism can offer a compact and efficient solution. Industries like oil and gas or food processing often use ball check valves because of their simplicity and effectiveness in preventing contamination from backflow. The tilting disc check valve is another popular type, where a disc tilts to close off reverse flow.

The symbol for this valve typically features a line representing the disc inside the valve body, angled to show the tilting motion. Tilting disc check valves are highly efficient and commonly used in large industrial systems, such as in power plants, to prevent backflow in pipelines where large volumes of fluids are in motion. In addition to these common variations, there are piston check valve symbol and diaphragm check valves, which each have distinct symbols in technical drawings. This type is used in applications requiring high-pressure resistance, such as in heavy machinery or oil and gas pipelines. The diaphragm check valve, on the other hand, uses a flexible diaphragm that seals the valve when reverse flow occurs. This type is ideal for sanitary applications, such as in food and beverage production, where contamination risks must be minimized. Check valves are used across a broad range of industries, each requiring specific types and symbol representations to match their operational needs.