Glass Reactors and Green Chemistry – Sustainable Practices in Chemical Synthesis

Glass reactors are revolutionizing the field of green chemistry by offering a more sustainable approach to chemical synthesis. Traditional chemical reactors, often made from metals or alloys, can pose significant environmental and health hazards due to their potential for corrosion and the release of toxic byproducts. In contrast, glass reactors, typically composed of borosilicate glass, provide a safer, cleaner alternative that aligns with the principles of green chemistry. One of the key advantages of glass reactors is their inert nature. Borosilicate glass is highly resistant to chemical reactions, which minimizes the risk of unwanted side reactions and contamination. This characteristic is particularly beneficial for reactions involving corrosive or reactive chemicals. The transparency of glass reactors also allows for real-time monitoring of the reaction process. Researchers can observe the progression of reactions without the need to open the reactor, reducing the risk of exposure to hazardous materials and minimizing the potential for contamination.

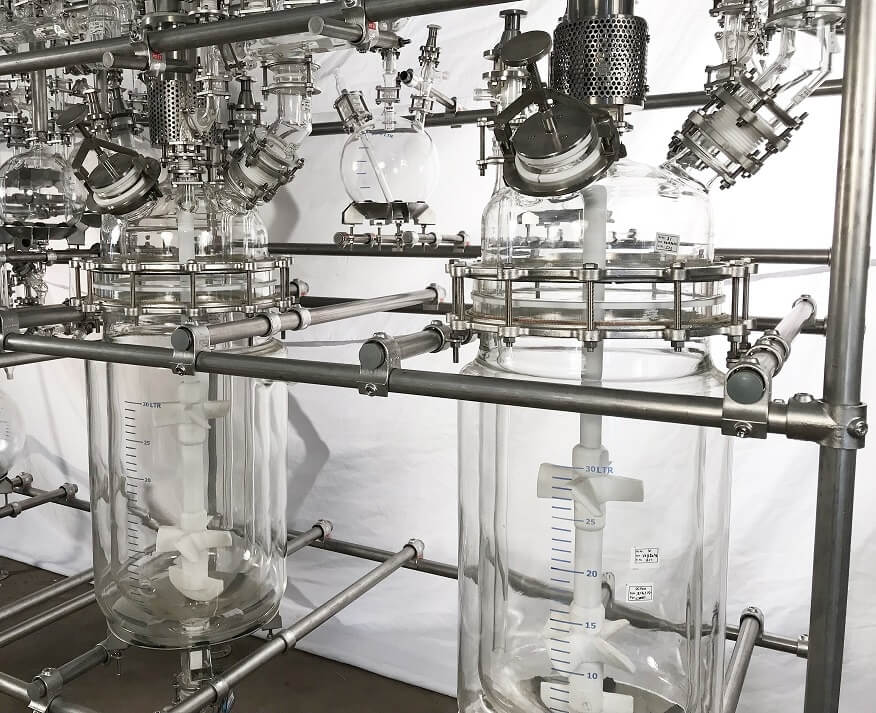

Glass reactors also contribute to sustainability by improving reaction efficiency and reducing waste. Their ability to operate under precise conditions enhances control over reaction parameters such as temperature and pressure. This precision can lead to higher yields and fewer byproducts, aligning with the green chemistry goal of maximizing atom economy. Additionally, glass reactors are easy to clean and sterilize, which reduces the need for harsh cleaning agents and minimizes waste generation. The versatility of glass reactors extends to their application in various chemical processes. They are commonly used in batch reactions, continuous flow reactions, and even in the development of pharmaceuticals and fine chemicals. In batch reactions, glass reactors enable precise temperature and agitation control, which can optimize reaction rates and product quality. In continuous flow reactions, the smooth inner surface of glass reactor ensures consistent flow and minimal fouling, which can enhance the efficiency and safety of chemical processes. Furthermore, glass reactors support the principles of green chemistry by facilitating the use of renewable and safer solvents.

Their compatibility with a wide range of solvents, including water and environmentally benign solvents, allows for the implementation of greener reaction conditions. This adaptability helps reduce the reliance on toxic or non-renewable solvents, contributing to a more sustainable chemical synthesis process. Despite their numerous advantages, GWSI glass reactors do have limitations. They are generally more fragile than their metal counterparts, which can pose risks during handling and operation. However, advancements in glass technology and design have improved their durability and safety. Researchers and engineers continue to innovate, developing reinforced glass and novel designs that enhance the resilience of these reactors while maintaining their environmental benefits. In summary, glass reactors represent a significant advancement in green chemistry by offering a safer, more efficient, and sustainable alternative to traditional metal reactors. Their inert nature, transparency, and precision contribute to improved reaction efficiency and reduced environmental impact.